- Get link

- X

- Other Apps

The types of projects include foundations industrial and commercial floors roads and highways and other exterior slab-on-grade hardscapes. If you have any questions about slab preparation products please call the Jahna main office in Avon Park at 863 453-4353 or use the quick contact form below.

Australian Construction Site Concrete Slab Preparation Waffle Slab Waffle Slab Waffle Slabs Are A Floating Construction Site Concrete Slab Concrete Footings

Australian Construction Site Concrete Slab Preparation Waffle Slab Waffle Slab Waffle Slabs Are A Floating Construction Site Concrete Slab Concrete Footings

Determine the proper depth by establishing the height of the concrete slab.

Concrete slab preparation. Step 1 Dig the ground down to the proper depth. Methods used for preparing the ground for concrete placement depend on the job. After preparing the base form work for concrete slab pavement is lay.

The forms can be of steel or timber. As with most things in life a solid foundation is necessary to build on. Most Concrete slabs are designed to have a compressive strength of 3000 psi.

Preparation is the most important aspect of pouring a concrete slab. Following a reputable concrete floor slab construction process will ensure that the slab lasts a sustained period. Is forming a 30 x 28 x 6 concrete slab for a garageIll sho.

A slab pour requires efficient planning so that all of the elements that go into producing a high-quality slab are done in time before the concrete sets and done correctly. Laying the groundwork Although they look smooth to the naked eye brand new concrete slabs are never completely flat. Drill the holes as deep as you can the entire length of the bit so the rebar fits snugly into the holes.

The Basics The bulk of the work for a new slab is in the excavation and form building. Click on HOW TO MIX CONCRETE if you want learn how to use bags of concrete mix to do your slab. Then figure on spending a day building the forms and another pouring the slab.

If you have to level a sloped site or bring in a lot of fill hire an excavator for a day to help prepare the site. Form work should be rigidly fix in position and must be well in advance from the point where concrete mix is to be place. The same is true for our solid and engineered hardwood floors.

Curing must start the same day as soon as you have finished the surface. Typically slabs are not designed with the extra reinforcing. Click on CONCRETE MIXING RATIOS to learn what the correct proportions of cement sand stone and water are to mix your own concrete by hand.

This video will teach you how to form a concrete slabMy company Days Concrete Floors Inc. CURING THE CONCRETE SLAB PROTECTING THE SURFACE AGAINST MOISTURE LOSS Moisten the surface and edges of the slab using a hose on a gentle spray twice daily for 7 days. How to Pour a Concrete Slab.

WE HAD A MASSIVE DRIVEWAY POUR IN THE FRONTYARD THIS DAY WHICH IS WHY THERE WAS SO MANY GUYS In this video we show you how to pour your basic 16 x 12 Concr. Click on the link CONCRETE SEALER to learn about properly cu. Concrete Slab Preparation Mission Hardwood believes in offering a turnkey solution and that is why we offer concrete slab preparation.

As liquid water can move through the concrete slab by means of channels such as cracks honeycombs or similar voids or even expansion and control joints. Concrete flexural strength is the ability of a slab wall or beam of concrete to resist failure under pressure to bend. When youre joining two concrete slabs connect the two with rebar to keep them at the same height.

If you have just installed concrete as a foundation for other coverings youre going to need floor preparation. Tie Into the Existing Slabs. Click on CONCRETE SLAB CALCULATOR to figure out how much concrete to order.

Insert chunks of rebar and tie them into the grid. The concrete slab construction process includes the preparation of formwork compaction of a slab bed placement of reinforcement pouring compacting finishing the concrete removing formwork and curing the concrete slab. Curing provides a continuous supply of moisture to ensure a better surface quality and a stronger slab.

The construction sequence starts with the removal of surface vegetation and topsoil excavation of high areas of grade surface. To achieve proper adhesion of the polymer system repairs must be made to eliminate this water. The depth of form work should be equal to the thickness of slab.

Knowing the right finishing tools to use and the right time to start bull floating and final troweling are essential to preventing dusting scaling and craze cracking of.

Garage Build Part 13 Preparing The Floor To Pour Concrete Youtube

Garage Build Part 13 Preparing The Floor To Pour Concrete Youtube

Subgrade And Subbase For Concrete Slabs

Subgrade And Subbase For Concrete Slabs

Concrete Slab Preparation Large Area Page 1 Line 17qq Com

Concrete Slab Preparation Large Area Page 1 Line 17qq Com

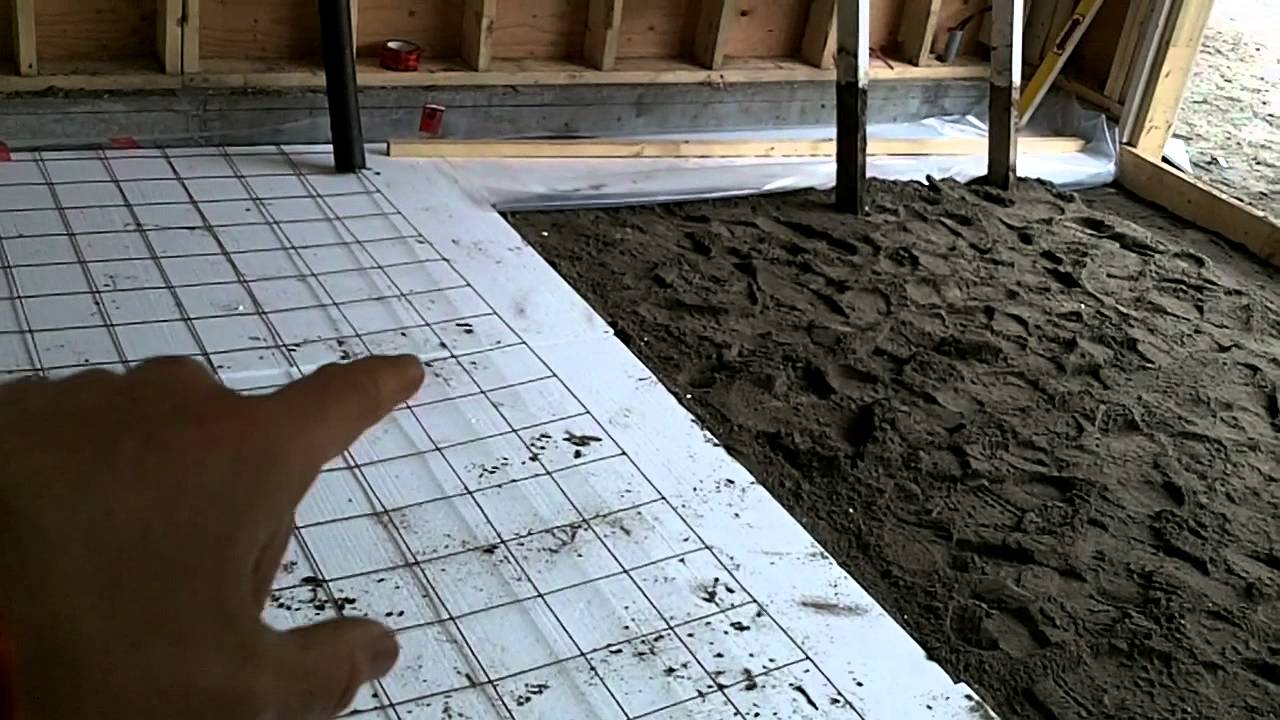

Preparation Of The Concrete Slab With An Iron Mesh On A Construction Stock Photo Picture And Royalty Free Image Image 149833933

Preparation Of The Concrete Slab With An Iron Mesh On A Construction Stock Photo Picture And Royalty Free Image Image 149833933

Concrete Slab Preparation Site Visit Episode 94 Youtube

Concrete Slab Preparation Site Visit Episode 94 Youtube

Floating Reinforced Concrete Concrete Slab Preparation Australian Construction Site Stock Footage Video Of Slab Reinforced 103684904

Floating Reinforced Concrete Concrete Slab Preparation Australian Construction Site Stock Footage Video Of Slab Reinforced 103684904

Concrete Grout Specimen Preparation A Sandblasting Of The Concrete Download Scientific Diagram

Concrete Grout Specimen Preparation A Sandblasting Of The Concrete Download Scientific Diagram

Garage Concrete Slab Preparation

Garage Concrete Slab Preparation

Preparation For Pouring A Concrete Slab In Construction Site Stock Photo Picture And Royalty Free Image Image 105153356

Preparation For Pouring A Concrete Slab In Construction Site Stock Photo Picture And Royalty Free Image Image 105153356

Residential Construction Process Impact Design Drafting

Residential Construction Process Impact Design Drafting

Preparing For A Topping Concrete Construction Magazine

Preparing For A Topping Concrete Construction Magazine

A Preparation Of Concrete Slab And B Normal Transducer Inspection Download Scientific Diagram

A Preparation Of Concrete Slab And B Normal Transducer Inspection Download Scientific Diagram

How To Prepare A Site For Concrete Base Forms And Rebar

How To Prepare A Site For Concrete Base Forms And Rebar

Comments

Post a Comment