- Get link

- X

- Other Apps

Without the Z clips the fiberglass would probably sink to the bottom or rise to the top of the concrete. Ad Santa Fe Top Source for Redi-Mix Concrete Portland Cement and Lime.

How To Build Concrete Forms Youtube

How To Build Concrete Forms Youtube

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features 2021.

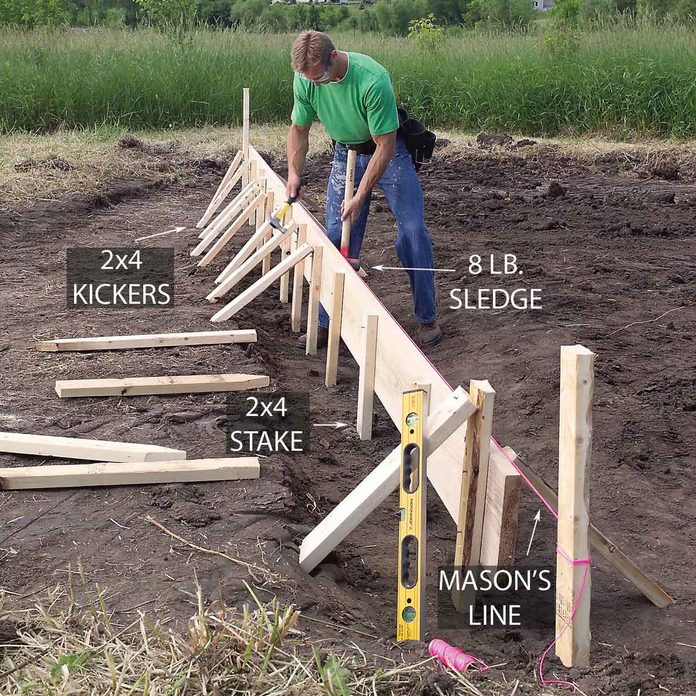

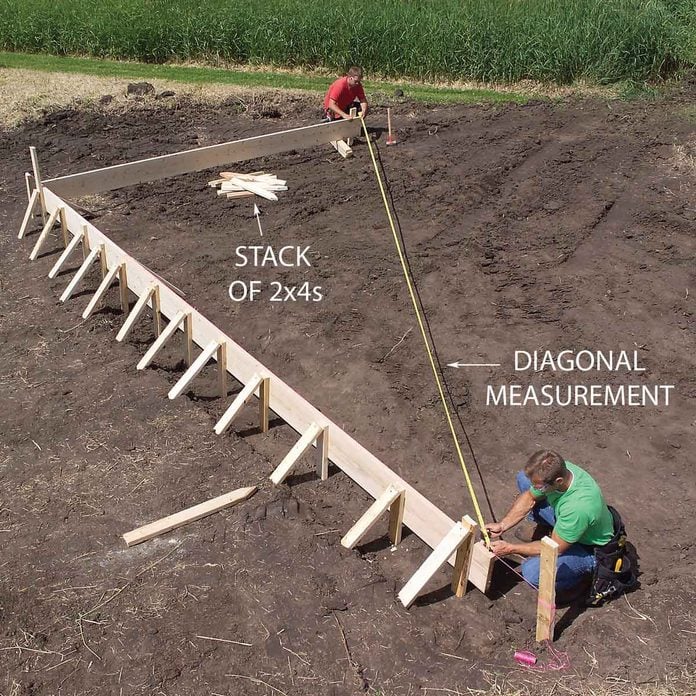

Setting concrete forms. A video on how to set up concrete forms. Ad Quality Concrete Mixing Plant. The most basic forms for concrete slabs where the concrete will not exceed 6 inches in height consist of wooden boards that are screwed or nailed to wood or metal stakes.

Ad Santa Fe Top Source for Redi-Mix Concrete Portland Cement and Lime. The stakes are driven into the prepared subbase and by using leveling devices such as hand levels laser levels or string lines contractors set the forming boards to the proper level or slope. Dewalt drill driver and 25 deck screws - We like these better than a hammer an nails for fastening the forms together.

This article will refer to a slab form wall forms have completely different requirements. The concrete takes the shape of the form or the mold in which it is contained. Forms have to have tight joints to prevent concrete from leaking through must be rigid to prevent the concrete from bowing out and must be strong enough to hold the concrete firmly in place.

The depth and width of the concrete placement determine the bracing and forming material required. The tools youll need for forming a concrete slab are. The Z clips help hold it in the middle.

Concrete forms can be defined as a solid barrier that helps to hold the fluid concrete in place until it hardens and acquire a particular shape. Its also easier to strip the forms when the slab pour is done. In addition to the above elements of cost planning of formwork operations should consider the overall.

Attach the Z clips to the fiberglass mesh and the durock. The forming system does not have a top or bottom and can be set up horizontally or vertically. The bracing prevents the concrete form work from wandering or moving when pouring concrete.

A string line may be used as a guide for setting forms and leveling forms or a laser level maybe used for the same purpose. Building a straight form for concrete is fairly simple as long as the correct techniques are used. Hammer nails tape measure string pencil stakes laser level.

Furthermore since the dado slots are placed 12 inches towards the center and 6 inches apart from each end for tie insertion the need for measuring or drilling for ties is effectively eliminated. The concrete form buildersetter will also have to brace forms to the concrete floor as well as brace the internal core walls. Ad Quality Concrete Mixing Plant.

Concrete forms provide a container for the fluid concrete and hold it in the proper shape until it can hold its own weight after fully hardening and drying. For the fiberglass to work correctly it needs to be in the center of the concrete. Cost for setting and stripping forms the contractor should allow for delays from weather equipment problems etc as well as cleaning and other miscellaneous expenses.

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms Forming Concrete With Wood Forms Youtube

Concrete Forms Forming Concrete With Wood Forms Youtube

A Construction Works In Cold Conditions Setting Forms For Pouring Stock Photo Picture And Royalty Free Image Image 114869634

A Construction Works In Cold Conditions Setting Forms For Pouring Stock Photo Picture And Royalty Free Image Image 114869634

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Building Concrete Form And Pouring A Slab Youtube

Building Concrete Form And Pouring A Slab Youtube

How To Build A Straight Form For Concrete 6 Steps With Pictures

How To Build A Straight Form For Concrete 6 Steps With Pictures

Diy Concrete Forms Forming The Foundation Footings Youtube

Diy Concrete Forms Forming The Foundation Footings Youtube

How To Prepare A Site For Concrete Base Forms And Rebar

How To Prepare A Site For Concrete Base Forms And Rebar

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

How To Maintain A Concrete Slab S Thickness At The Center During Pouring Quora

Driveway Concrete Form Diy Carport Types Of Concrete Pouring Concrete Slab

Driveway Concrete Form Diy Carport Types Of Concrete Pouring Concrete Slab

Setting Concrete Forms Construction Site Build Stock Photo Edit Now 605957597

Setting Concrete Forms Construction Site Build Stock Photo Edit Now 605957597

Part One Preparing The Forms For Concrete Youtube

Part One Preparing The Forms For Concrete Youtube

Forming Concrete With Plastic Forms Youtube

Forming Concrete With Plastic Forms Youtube

Comments

Post a Comment